| Note: This article may contain affiliate links, which means if you make a purchase following our links won’t cost you extra, but we may earn a commission. Learn more |

Air dryers not purging is a common issue faced in various vehicles. This problem can occur in different models, including Bendix, Freightliner, Wabco, and Volvo.

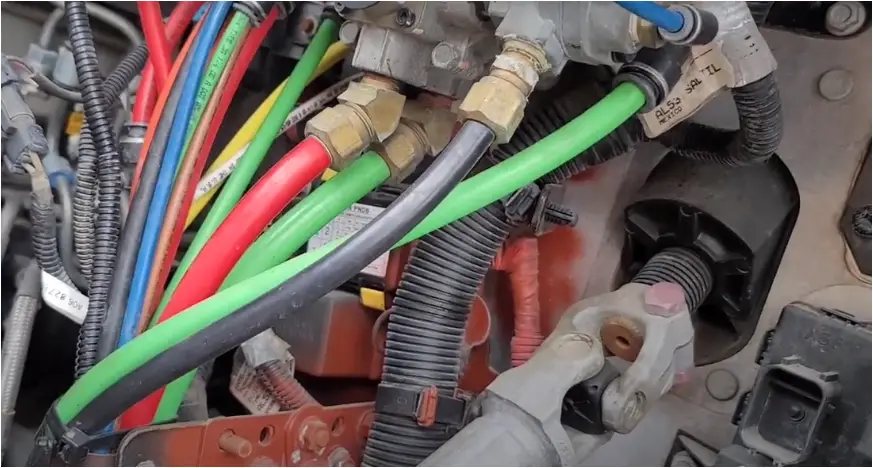

The air dryer in a vehicle plays a crucial role in maintaining the efficiency of the braking system. It removes moisture and contaminants from the compressed air before it reaches the air reservoirs and the components of the brake system. If the air dryer is not purging, it can lead to a buildup of moisture and contaminants, which can cause damage to the brake system and other components.

The purge valve is a critical component of the air dryer system. If it sticks, it can prevent the air dryer from purging, leading to the aforementioned issues. In such cases, the purge valve may need replacement.

Bad air dryer symptoms can vary. One common symptom is the air dryer blowing air out the bottom. This can indicate a problem with the purge valve or a bad air dryer filter. If the filter is bad, it can prevent the air dryer from purging properly.

In the case of a Bendix air dryer not purging, troubleshooting may involve checking the purge valve and the filter. If the purge valve is leaking, it can prevent the air dryer from purging. A leaking purge valve will need to be replaced to restore the functionality of the air dryer.

Learn More: Air Dryer Purging Constantly!

How Does an Air Dryer Purge Valve Work

The air dryer purge valve is a critical component in the air brake system of heavy-duty vehicles. Its primary function is to remove moisture and contaminants from the compressed air before it reaches the air brake system. The operation of the purge valve is a fascinating process.

The air dryer is connected to the air compressor and the air reservoir. As the air compressor generates compressed air, it passes through the air dryer.

The purge valve, located within the air dryer, opens and closes at specific intervals, allowing the air to flow into a desiccant bed. This desiccant bed absorbs moisture and contaminants from the compressed air.

Once the air has been cleaned, the purge valve closes, trapping the moisture and contaminants in the desiccant bed. The clean, dry air is then sent to the air reservoir, ready for use in the air brake system. The purge valve plays a crucial role in maintaining the efficiency and longevity of the air brake system.

Common Reasons for Air Dryers Not Purging

1. Blocked Purge Valve

A blocked purge valve is a common reason for an air dryer not purging. This can occur due to the accumulation of debris or dirt within the valve. The blockage prevents the purge valve from opening, thus inhibiting the purging process.

Solution: Cleaning or Replacing the Purge Valve

To rectify this issue, the purge valve needs to be cleaned or replaced. Cleaning involves removing the valve and using a suitable cleaning solution to remove any debris. If cleaning does not resolve the issue, the valve may need to be replaced.

2. Faulty Purge Valve

A faulty purge valve can also prevent an air dryer from purging. This can be due to wear and tear, or a manufacturing defect.

Solution: Replacing the Purge Valve

In this case, the solution is to replace the faulty purge valve with a new one. This should be done by a professional to ensure proper installation and operation.

3. Insufficient Air Pressure

Insufficient air pressure can prevent the air dryer from purging. The air dryer requires a certain level of pressure to operate effectively, and if this is not met, it may not purge.

Solution: Checking and Adjusting Air Pressure

The air pressure should be checked using a pressure gauge. If the pressure is found to be below the required level, it should be adjusted to the correct level.

4. Damaged Desiccant

The desiccant in the air dryer can become damaged over time, which can prevent the air dryer from purging. This can be due to overuse or exposure to harsh conditions.

Solution: Replacing the Desiccant

The damaged desiccant should be replaced with a new one. This should be done by a professional to ensure that the new desiccant is installed correctly and the air dryer can function properly.

5. Electrical Issues

Electrical issues can also prevent an air dryer from purging. This can be due to a faulty electrical connection or a malfunctioning electrical component.

Solution: Electrical Inspection and Repair

An electrical inspection should be carried out to identify any issues. Any faulty connections or components should be repaired or replaced to ensure the air dryer can operate effectively.

Bad Air Dryer Purge Valve Symptoms

Recognizing the signs of a faulty air dryer purge valve is crucial for maintaining the performance of your vehicle’s air brake system.

1. One of the most common symptoms is the constant expulsion of air. If the purge valve is not closing properly, it will continue to release air even after the air system is charged.

2. Another symptom is the presence of excessive moisture or oil in the air brake system. If the purge valve is not functioning correctly, it may not be able to remove all the moisture and contaminants from the compressed air. This can lead to corrosion and damage to the air brake system.

3. A malfunctioning purge valve can cause the air compressor to run continuously. This is because the air system is not able to maintain the required pressure due to the constant release of air. This can lead to increased fuel consumption and wear and tear on the air compressor.

The Air Dryer Purge Valve Leaking

A leaking air dryer purge valve is a serious issue that needs immediate attention. The leak can occur due to various reasons such as a damaged seal, a cracked valve body, or a worn-out valve stem.

The most common sign of a leaking purge valve is a continuous hissing sound from the air dryer. This is caused by the constant release of air due to the leak.

A leaking purge valve can lead to a drop in the air pressure in the brake system. This can affect the performance of the air brakes and can potentially lead to brake failure.

Therefore, it is crucial to address this issue promptly to ensure the safety and performance of the vehicle.

Maintaining Tips

1. Regular inspection and maintenance of the air dryer purge valve can help prevent issues and ensure the efficient operation of the air brake system. One of the key maintenance tasks is to check the purge valve for leaks regularly. This can be done by listening for a hissing sound or by checking for a drop in air pressure.

2. It is also advisable to replace the desiccant bed at regular intervals. Over time, the desiccant bed can become saturated with moisture and contaminants, reducing its effectiveness. Replacing the desiccant bed can help maintain the efficiency of the purge valve.

3. If the purge valve is found to be faulty or leaking, it should be replaced immediately. Using a faulty purge valve can lead to serious issues with the air brake system and can potentially compromise the safety of the vehicle.

Learn Also: Air Dryer Troubleshooting Guide